Project objective: installation of a new optical and 100% CCIT Inspection line for the inspection of liquid, powder, and lyophilized vials. Line speed 200-350 vials/min.

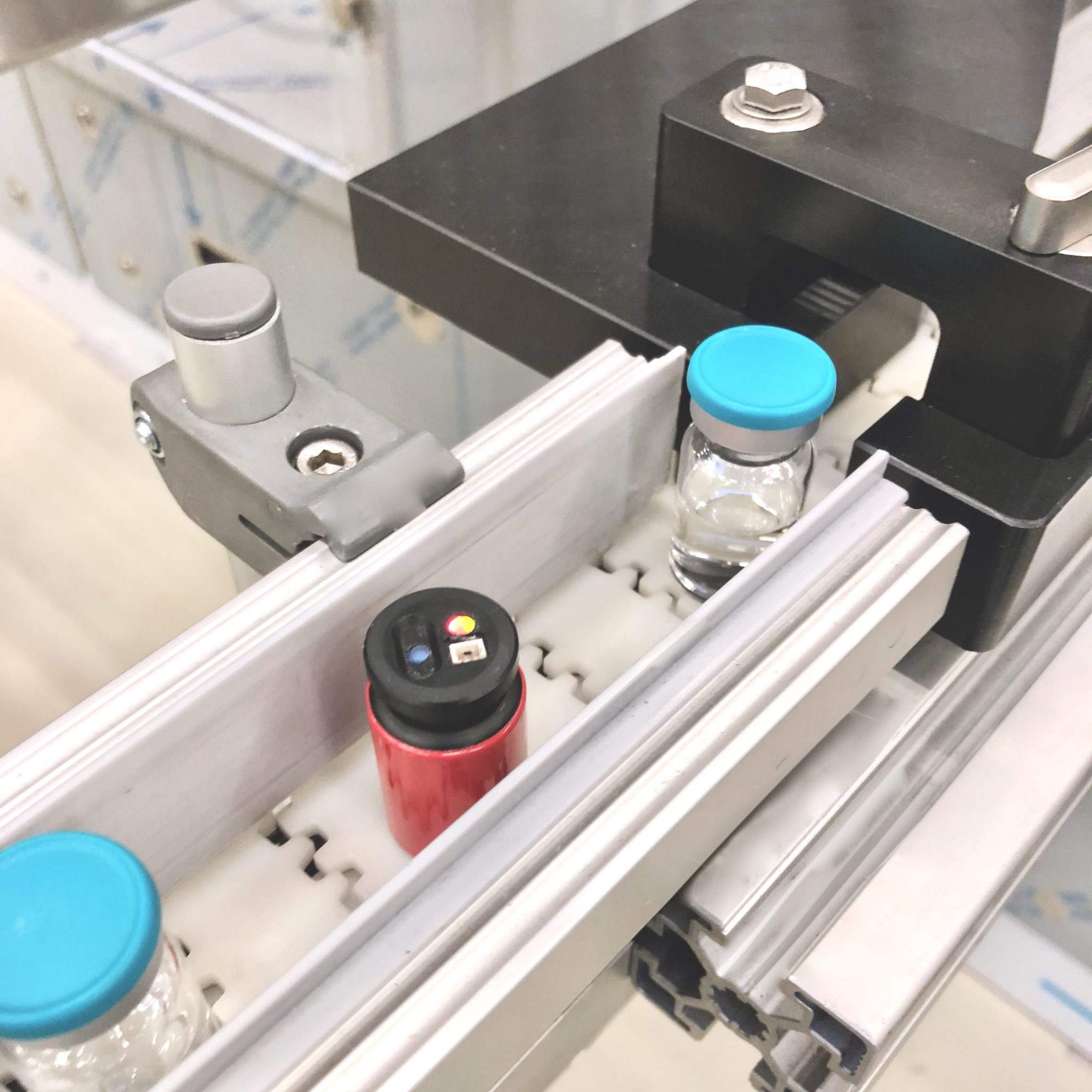

New equipment: fully-automated inspection machine (inclusive upside down module) and two semi-automated inspection machines for detection of defects and non-conformities in vials, 100% CCIT machine (consisting of vacuum decay and HSA modules) and separate headspace analyzer for verification of vial integrity, two robotic tray loaders for re-traying of vials into trays and two reconciliation cameras to provide an accurate count of re-trayed vials in trays.

New utilities: compressed air

New rooms: controlled environment (temperature, humidity)

Project budget: 11 M CHF

Provided services: project management and execution (engineering and qualification), coordination of suppliers, review of design documentation, evaluation of changes, offers, search for alternative suppliers, update of requirement specification, performance of drone tests for the improvement of product handling, issuing, execution and completion of qualification: qualification plan, risk analyses (pFMEA, eFMEA), DQ, IQ, OQ, IOQ, IT, OT, FT, QES, FAT, SAT.

Project status: successfully completed, line in production